Mzere Wopangira Sitima ya RDS13 CNC Wodula ndi Kubowola

| Chinthu | gawo | Kufotokozera |

| Chitsanzo cha njanji yoyambira | Mtundu wa zinthu | 50Kg/m2,60 kg/m,75 kg/m kuuma 340~400HB |

| Sitima yapakati yachitsulo cha alloy, choyikapo chachitsulo cha alloy, kuuma 38 HRC~45 HRC | ||

| Kukula kwa njanji | Kutalika kwa zinthu zopangira | 2000~1250mm |

| Zofunikira pakukonzekera | Zinthu Zofunikakutalika | 1300~800mm |

| Zinthu Zofunikakulekerera kutalika | ± 1mm | |

| Kukhazikika kwa nkhope kumapeto | <0.5mm | |

| Kubowola m'mimba mwake | φ31~φ60mm | |

| M'mimba mwake wa dzenjekulolerana | 0~0.5mm | |

| Kutalika kwa dzenje | 60~100mm | |

| Main technical parameters of machine | Njira yocheka | Chocheka chozungulira (chothamanga kwambiri) |

| Mphamvu ya injini ya spindle | 37kW | |

| M'mimba mwake wa tsamba locheka | Φ660mm | |

| Liwiro lalikulu losuntha la X axis | 25m/mphindi | |

| Liwiro lalikulu kwambiri losuntha la Z axis | 6m/mphindi | |

| Mtundu wa spindle pobowola | BT50 | |

| KubowolaLiwiro la spindle | 3000r/mphindi | |

| KubowolaMphamvu ya injini ya servo ya spindle | 37kW | |

| Liwiro lalikulu kwambiri losuntha la X, Y, Z axis | 12m/mphindi | |

| Mtundu wa spindle wozungulira | NT40 | |

| Chopindika cha spindle cha chamfering RPM Max. | 1000 | |

| Mphamvu ya injini ya spindle yozungulira | 2.2 kW | |

| Liwiro la kuyenda kwa Y2 axis ndi Z2 axis | 10m/mphindi | |

| Chuck yamaginito yokhazikika yamagetsi | 250×200×140mm(china200 × 200 × 140 mm) | |

| Kugwira ntchito | ≥250N/cm² | |

| Njira yochotsera chips | 2seti | |

| Mtundu wa chonyamulira cha chip | Unyolo wosalala | |

| Liwiro lochotsa chip | 2m/mphindi | |

| Dongosolo la CNC | Siemens828D | |

| Chiwerengero cha machitidwe a CNC | Seti ziwiri | |

| Chiwerengero cha nkhwangwa za CNC | 6+1 axis,2+1 axis | |

| Kutalika kwa tebulo logwirira ntchito | 700mm | |

| Kutalika kwa tebulo logwirira ntchito | pafupifupi 37.8m×8m×3.4m |

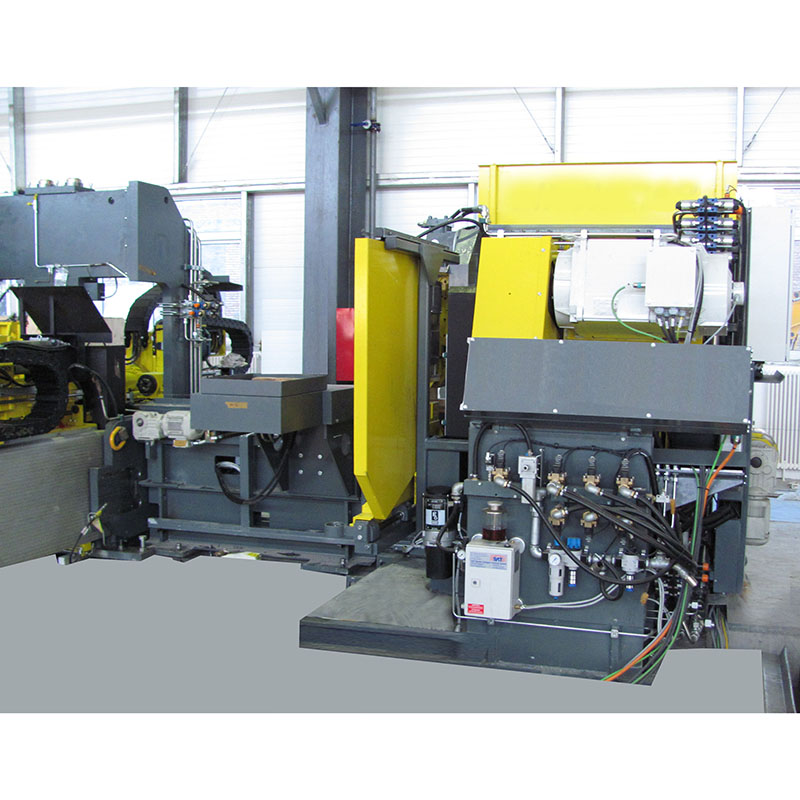

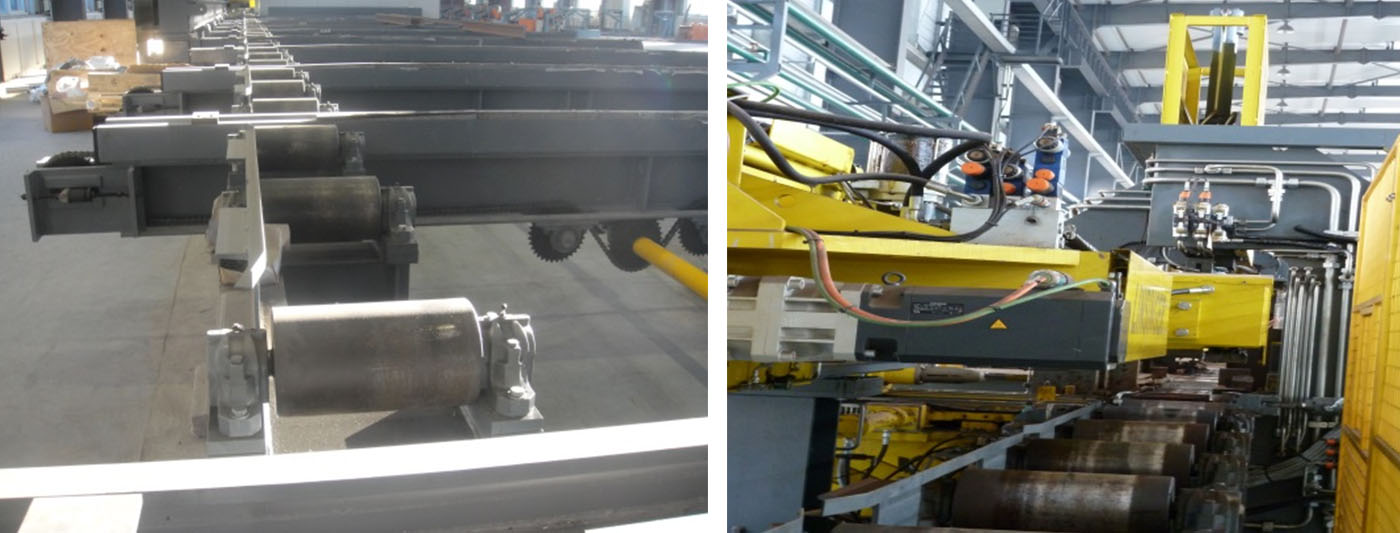

1. Pali chipangizo chochotsera tchipisi cha tsamba la saw pa chipangizo chodulira, chomwe chimayang'anira kuchotsa utsi wa utuchi pa tsamba la saw. Chipangizo choziziritsira ndi kudzola chimapaka mafuta ndikuziziritsa malo odulira, zomwe zimapangitsa kuti tsamba la saw likhale ndi moyo wabwino. Zingwe zowongolera, ndipo mzere woyenda umayikidwa pa bedi la makina.

2. Dongosolo la ma code

Dongosolo lolembera ma code limayikidwa kunja kwa power head ram, ndipo lili ndi kompyuta yosungira mapulogalamu kuti ipange ndikuwongolera dongosolo lolembera ma code.

3. Chipangizo chobowolera

Kapangidwe ka mzati kamagwiritsidwa ntchito, ndipo mzati umagwiritsa ntchito kapangidwe kolumikizidwa ndi mbale yachitsulo. Pambuyo pokonza ndi kukalamba kopangidwa, kukhazikika kwa kulondola kwa kukonza kumatsimikizika.

4. Chikwama chamutu chobowolera

Chikwama chobowolera ndi chopangidwa ngati ram chokhala ndi kulimba kwamphamvu. Lamba wokhazikika nthawi zambiri amakhala ndi mphamvu yokoka, amakhala nthawi yayitali, phokoso lochepa komanso kugwedezeka kochepa akamathamanga mwachangu. Chopondera cholondola chimaziziritsidwa mkati ndipo chili ndi dzenje, ndipo chili ndi makina olumikizira zikhadabo za 45° four-petal. Kumbuyo kwa chopondera cholondola kuli ndi silinda yobowolera ya hydraulic kuti zikhale zosavuta kusintha zida.

5. Benchi logwirira ntchito

Benchi yogwirira ntchito imagwiritsa ntchito kapangidwe ka kuwotcherera mbale zachitsulo, chithandizo chisanachitike chimachitika musanawotchetse, ndipo mutawotcherera, mpumulo wa nkhawa ndi chithandizo cha kutentha kwa ukalamba zimachitika kuti zitsimikizire kulondola ndi kukhazikika.

6. Njira yochotsera tchipisi

Chotengera cha chip chokhachokha ndi chamtundu wa flat chain, chokhala ndi ma seti awiri. Seti imodzi imagwiritsidwa ntchito pa chipangizo chodulira ndipo imayikidwa pansi pa tsamba la saw. Seti inayo imagwiritsidwa ntchito pa chipangizo chobowolera, chomwe chimayikidwa pakati pa bedi ndi benchi yogwirira ntchito. Mafayilo achitsulo amagwera pa chipangizo chodulira chip kudzera pa chitsogozo cha chip pa benchi yogwirira ntchito, ndipo mafayilo achitsulo amanyamulidwa kupita ku bokosi losungira chitsulo pamutu kudzera pa chipangizo chodulira chip.

7. Dongosolo lopaka mafuta

Pali magulu awiri a makina odzola okha okhazikika, limodzi la makina odulira ndi lina la makina obowola. Makina odzola okha okhazikika amachita mafuta ochulukirapo pa mzere wozungulira wotsogolera, mpira wozungulira, ndi rack ndi pinion kuti zitsimikizire kulondola kwawo ndi nthawi yogwira ntchito.

8. Dongosolo lamagetsi

Dongosolo lamagetsi limagwiritsa ntchito njira yowongolera manambala ya Siemens 828D, yonse ili ndi ma seti awiri, seti imodzi imagwiritsidwa ntchito kuwongolera gawo locheka, choyimitsa chodyetsa chopingasa, tebulo loyimitsa chodyetsa ndi tebulo lapakati loyimitsa. Seti ina imagwiritsidwa ntchito kuwongolera gawo lobowola, benchi logwirira ntchito 1, choyimitsa chotsitsa chopingasa ndi benchi logwirira ntchito.

| Ayi. | Chinthu | Mtundu | Chiyambi |

| 1 | Peyala yowongolera mzere | HIWIN | Taiwan, China |

| 2 | Dongosolo la CNC 828D | Siemens | Germany |

| 3 | Smota ya ervo | Siemens | Germany |

| 4 | Dongosolo lolemba ma code | Chosindikizira cha LDMinkjet | Shanghai, China |

| 5 | Pampu yamafuta a hydraulic | Justmark | Taiwan, China |

| 6 | Kokani unyolo | CPS | South Korea |

| 7 | Magiya, ma racks | APEX | Taiwan, China |

| 8 | Chochepetsera bwino zinthu | APEX | Taiwan, China |

| 9 | spindle yolondola | KENTURN | Taiwan, China |

| 10 | Zigawo zazikulu zamagetsi | Schneider | France |

Dziwani: Wogulitsa amene ali pamwambawa ndi wokhazikika. Angasinthidwe ndi zinthu zomwezo za mtundu wina ngati wogulitsa amene ali pamwambawa sangathe kupereka zinthuzo ngati pangakhale zinthu zina zapadera.

Mbiri Yachidule ya Kampani  Zambiri Za Fakitale

Zambiri Za Fakitale  Mphamvu Yopanga Pachaka

Mphamvu Yopanga Pachaka  Luso la Malonda

Luso la Malonda