Makina obowola a PLM Series CNC Gantry opangidwa ndi mafoni

| Item | Name | gawo | |||

| PLM3030-2 | PLM4040-2 | PLM5050A-2 | PLM6060-2 | ||

| Machining ochulukazinthukukula | Utali x m'lifupi | 3000*3000 mm | 4000×4000 mm | 5000×5000 mm | 5000×5000 mm |

| Makulidwe a mbale yokonzedwa kwambiri | 250 mm, Imatha kukula mpaka 380mm | ||||

| Ntchitotebulo | Kukula kwa benchi | 3500×3000 mm | 4500×4000 mm | 5500×4000 mm | 5500×4000 mm |

| M'lifupi mwa T-groove | 28 mm | ||||

| Lwokhala ndi denga | 3tzotsatsa/㎡ | ||||

| KubowolaChokulungira | Pazipitakuboolam'mimba mwake wa dzenje | φ60 mm | |||

| Chiŵerengero chachikuluKutalika kwa Chida vs. Kukula kwa Bowo | ≤10()Koronakabidekuboola) | ||||

| ChokulungiraRPM | 30-3000 r/mphindi | ||||

| Chopopera cha spindle | BT50 | ||||

| Mphamvu ya injini ya spindle | 2 × 22kW | ||||

| Mphamvu yayikulu ya spindlen≤750r/mphindi | 280Nm | ||||

| Mtunda kuchokera kumunsi kwa nkhope yaspindleku tebulo logwirira ntchito | 280—780 mm ()Sinthani malinga ndizinthumakulidwe) | ||||

| Kusuntha kwa gantry longitudinal (x-axis) | Kukwapula kwakukulu | 3000 mm | 4000 mm | 5000 mm | |

| Liwiro losuntha la X-axis | 0—8m/mphindi | ||||

| Mphamvu ya injini ya servo ya X-axis | 2 × 2.7kW | ||||

| Pkulondola kwa malo | X-axis、Y-axis | 0.06mm/ yonsesitiroko | 0.08mm/ yonsesitiroko | 0.10mm/ yonsesitiroko | |

| Kubwereza kulondola kwa malo | X-axis、Y-axis | 0.035mm/ yonsesitiroko | 0.04mm/ yonsesitiroko | 0.05mm/ yonsesitiroko | |

| Dongosolo la hayidiroliki | Kuthamanga / kuyenda kwa pampu ya hydraulic | 15MPa /25L/mphindi | |||

| Mphamvu ya injini ya pampu ya hydraulic | 3.0 kW | ||||

| Dongosolo la pneumatic | Kuthamanga kwa mpweya | 0.5 Mpa | |||

| Kuchotsa ndi kuziziritsa tchipisi | Mtundu wa chonyamulira cha chip | Unyolo wosalala | |||

| Chiwerengero cha chonyamulira chip | 2 | ||||

| Liwiro lochotsa chip | 1m/mphindi | ||||

| Mphamvu ya injini ya Chip conveyor | 2 × 0.75kW | ||||

| Kuziziritsa | Kuziziritsa kwamkati + kuziziritsa kwakunja | ||||

| Kupanikizika kwakukulu | 2MPa | ||||

| Kuthamanga kwakukulu | 2 × 50L/mphindi | ||||

| Dongosolo lamagetsi | CNC | Siemens 828D | |||

| CNCmzereNambala | 6 | ||||

| Mphamvu yonse ya galimoto | Pafupifupi 75kW | ||||

| Miyeso yonse ya chida cha makina | Kutalika × Kutalika × Kutalika | Zokhudza 8m×8m×3m | Zokhudza9m×9m×3m | Zokhudza10m×10m×3m | Zokhudza10m×10m×3m |

| Kulemera konse kwa chida cha makina | Pafupifupi 32t | Zokhudza40t | Zokhudza48t | ||

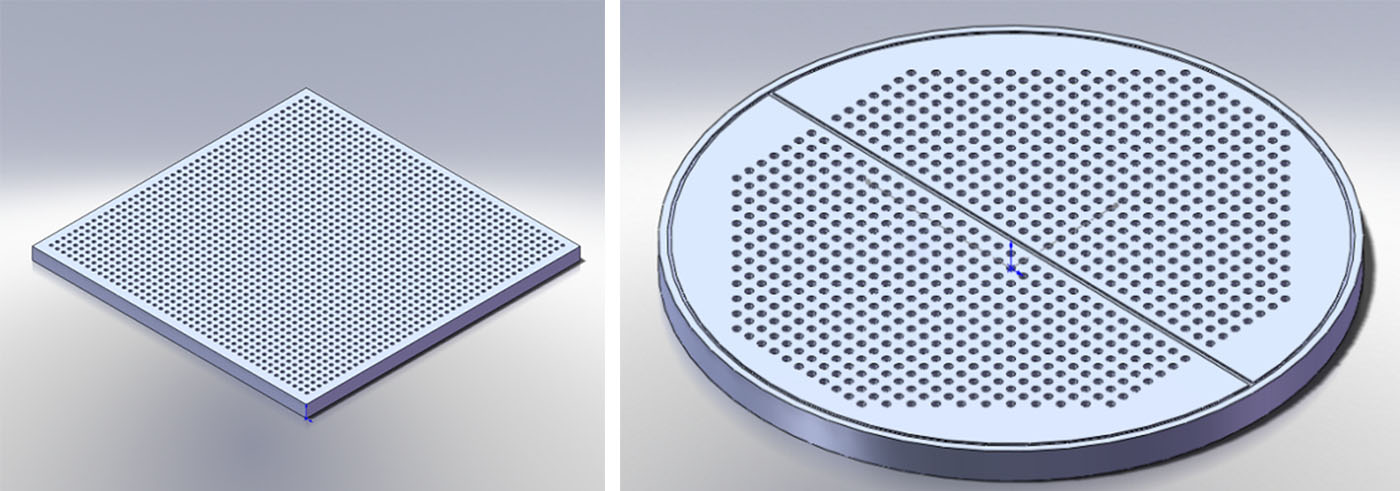

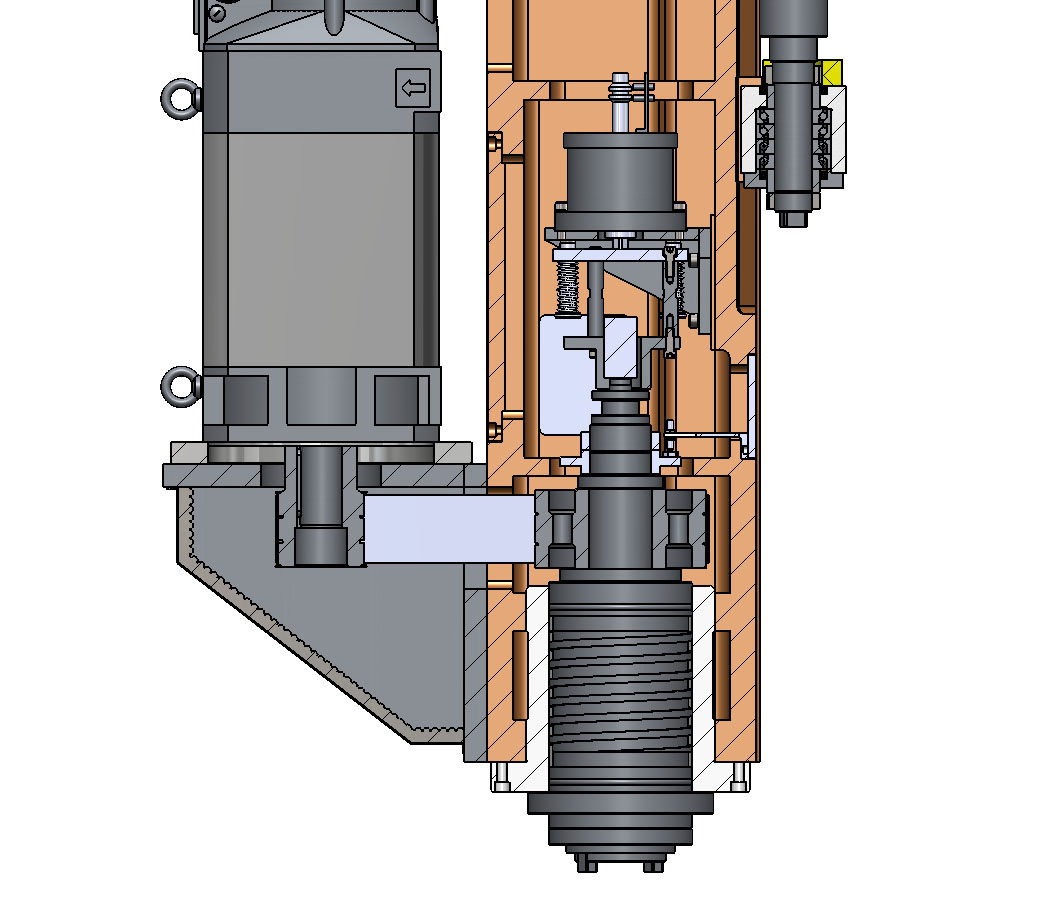

1. Makinawa amapangidwa makamaka ndi bedi ndi mzati, mtanda ndi tebulo lotsetsereka lopingasa, bokosi lamphamvu la mtundu wa ram type drilling, tebulo logwirira ntchito, chotengera cha chip, dongosolo la hydraulic, dongosolo la pneumatic, dongosolo loziziritsira, dongosolo lopaka mafuta pakati, dongosolo lamagetsi, ndi zina zotero.

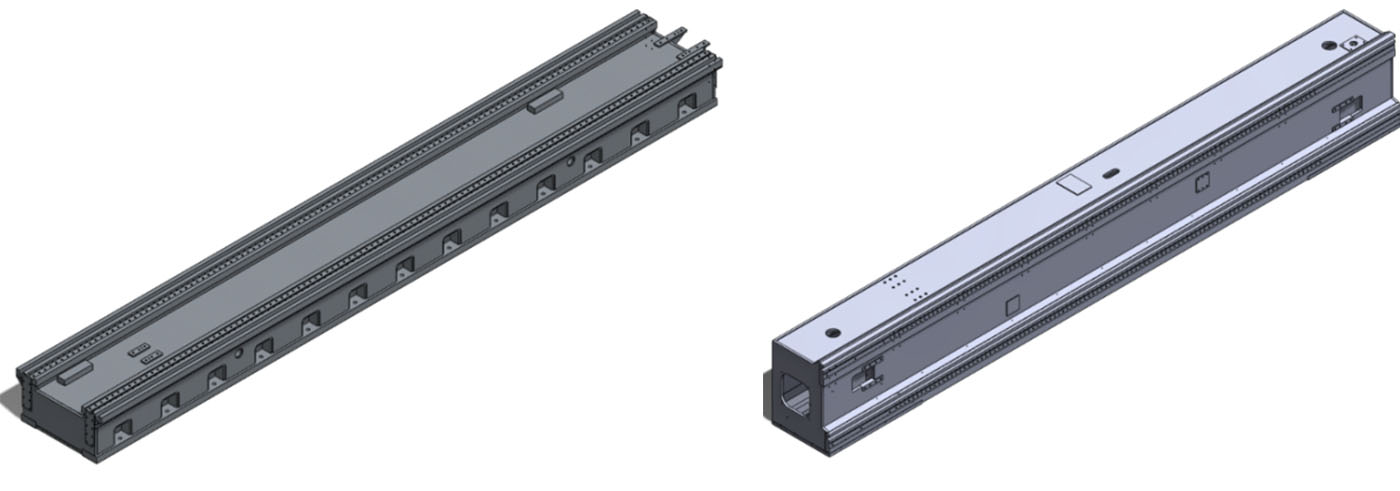

2. Maziko oyendetsera zinthu zolimba kwambiri, bere limagwiritsa ntchito screw yolondola kwambiri. Malo oyambira okhazikika nthawi yayitali amatsimikizira kulimba kwa axial. Bearing imalimbikitsidwa kale ndi nati yotsekera, ndipo screw yotsogolera imalimbikitsidwa kale. Kuchuluka kotambasula kumatsimikiziridwa malinga ndi kusintha kwa kutentha ndi kutalika kwa screw yotsogolera kuti zitsimikizire kuti kulondola kwa malo a screw yotsogolera sikusintha kutentha kukakwera.

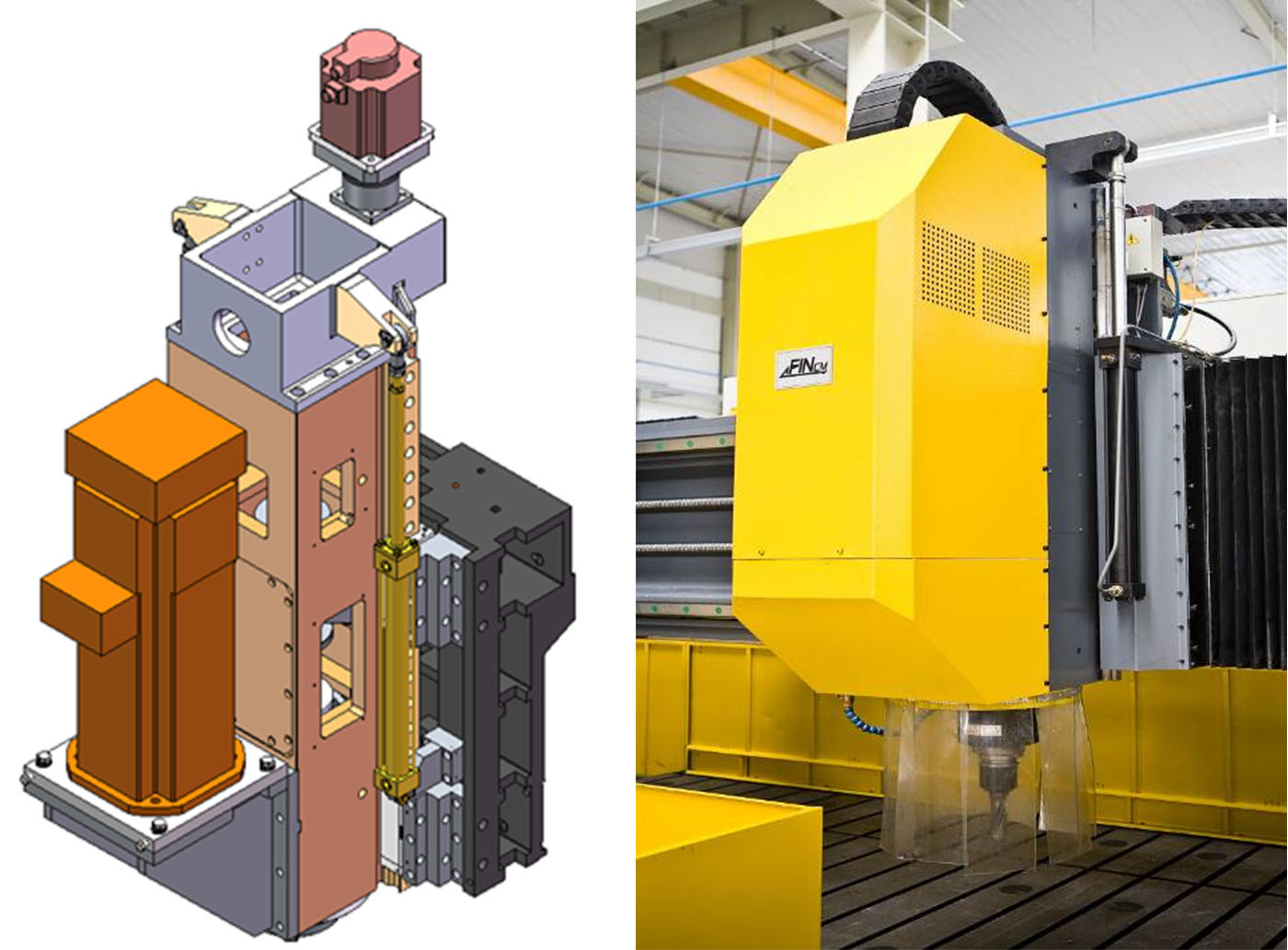

Mutu wa mphamvu yobowola ndi kugaya

3. Kuyenda koyima (Z-axis) kwa mutu wamagetsi kumatsogozedwa ndi ma linear roller guides awiri okonzedwa pa ram, okhala ndi chitsogozo chabwino, kukana kugwedezeka kwambiri komanso kukhudzika kochepa. Choyendetsa cha screw cha mpira chimayendetsedwa ndi servo motor kudzera mu precision planetary reducer, yomwe ili ndi mphamvu yayikulu yodyetsa.

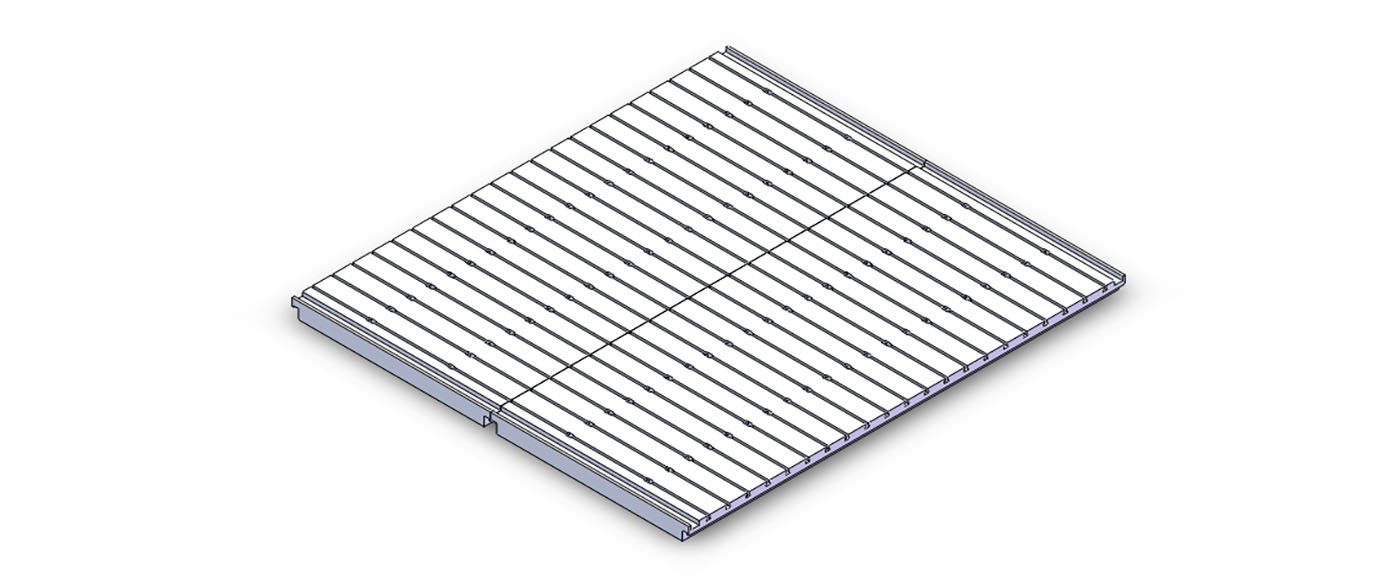

4. Makinawa amagwiritsa ntchito ma chip conveyor awiri a flat chain mbali zonse ziwiri za worktable. Ma chips achitsulo ndi coolant amasonkhanitsidwa mu chip conveyor, ndipo ma chips achitsulo amasamutsidwa kupita ku chip conveyor, zomwe zimakhala zosavuta kuchotsa ma chip; coolant imabwezeretsedwanso.

5. Makinawa amapereka njira ziwiri zoziziritsira—kuzizira mkati ndi kuzizira kunja, zomwe zimapereka mafuta okwanira ndi kuziziritsa ku chida ndizinthupanthawi yodula tchipisi, zomwe zimatsimikizira bwinokuboolakhalidwe labwino. Bokosi loziziritsira lili ndi zida zodziwira mulingo wamadzimadzi ndi zida zochenjeza, ndipo kuthamanga kozizira kokhazikika ndi 2MPa.

spindle yolondola

6. Zitsulo zowongolera za X-axis mbali zonse ziwiri za makina zili ndi zophimba zoteteza zachitsulo chosapanga dzimbiri, ndipo zitsulo zowongolera za Y-axis zili ndi zophimba zoteteza zosinthasintha mbali zonse ziwiri.

Chonyamulira tchipisi

Chipangizo choziziritsira

Chipangizo chodzipangira mafuta chokha

7. Makinawa alinso ndi chopezera m'mphepete mwa photoelectric kuti chithandize kuyika mbale yozungulira.

Siemens CNC System

| Ayi. | Dzina | Mtundu | Dziko |

| 1 | Sitima yowongolera yolunjika | HIWIN kapena PMI | Taiwan, China |

| 2 | Dongosolo Lowongolera la CNC | Siemens | Germany |

| 3 | Servo motor ndi dalaivala | Siemens | Germany |

| 4 | spindle yolondola | KENTURN kapena SPINTECH | Taiwan, China |

| 5 | Valavu yamadzimadzi | YUKEN KAPENA Justmark | Japan |

| 6 | Pompo yamafuta | Justmark | Taiwan, China |

| 7 | Dongosolo lodzola lokha | BIJUR KAPENA HERG | USA kapena Japan |

| 8 | Mabatani, magetsi owunikira ndi zida zina zazikulu zamagetsi | SCHBEIDER/ABB | France / Germany |

Dziwani: Wogulitsa amene ali pamwambawa ndi wokhazikika. Angasinthidwe ndi zinthu zomwezo za mtundu wina ngati wogulitsa amene ali pamwambawa sangathe kupereka zinthuzo ngati pangakhale zinthu zina zapadera.

Mbiri Yachidule ya Kampani  Zambiri Za Fakitale

Zambiri Za Fakitale  Mphamvu Yopanga Pachaka

Mphamvu Yopanga Pachaka  Luso la Malonda

Luso la Malonda