Makina Obowola a PLD7030-2 Gantry Mobile CNC Plate

| Pazipitambalekukula | Utali x m'lifupi | 7000x3000mm |

| Tkusokonezeka | 200mm | |

| Tebulo logwirira ntchito | Kukula kwa malo otsetsereka a T | 22mm |

| Mutu wa mphamvu yobowola | Kuchuluka | 2 |

| Kubowoladzenjemtunda wa m'mimba mwake | Φ12-Φ50mm | |

| RPM(mafupipafupi osinthasintha) | 120-560r/mphindi | |

| Mzere wozungulira wa spindle | Nambala 4 | |

| Mphamvu ya injini ya spindle | 2X7.5kW | |

| Kusuntha kwa gantry longitudinal (x-axis) | Kugundana kwa X-axis | 10000mm |

| Liwiro losuntha la X-axis | 0-8m/mphindi | |

| Mphamvu ya injini ya servo ya X-axis | 2x2.0kW | |

| Kusuntha kwa mbali ya mutu wa mphamvu (Y-axis) | Ulendo wa Y-axis | 3000mm |

| Liwiro losuntha la Y-axis | 0-8m/mphindi | |

| Mphamvu ya injini ya servo ya Y-axis | 2X1.5kW | |

| Kuyenda kwa mphamvu ya mutu (Z axis) | Kukwapula kwa Z-axis | 350mm |

| Chiŵerengero cha chakudya cha Z-axis | 0-4000mm/mphindi | |

| Mphamvu ya mota ya Z-axis servo | 2X1.5kW | |

| Chip conveyor ndi kuziziritsa | Mphamvu ya injini ya Chip conveyor | 0.75kW |

| Mphamvu ya injini ya pampu yozizira | 0.45kW | |

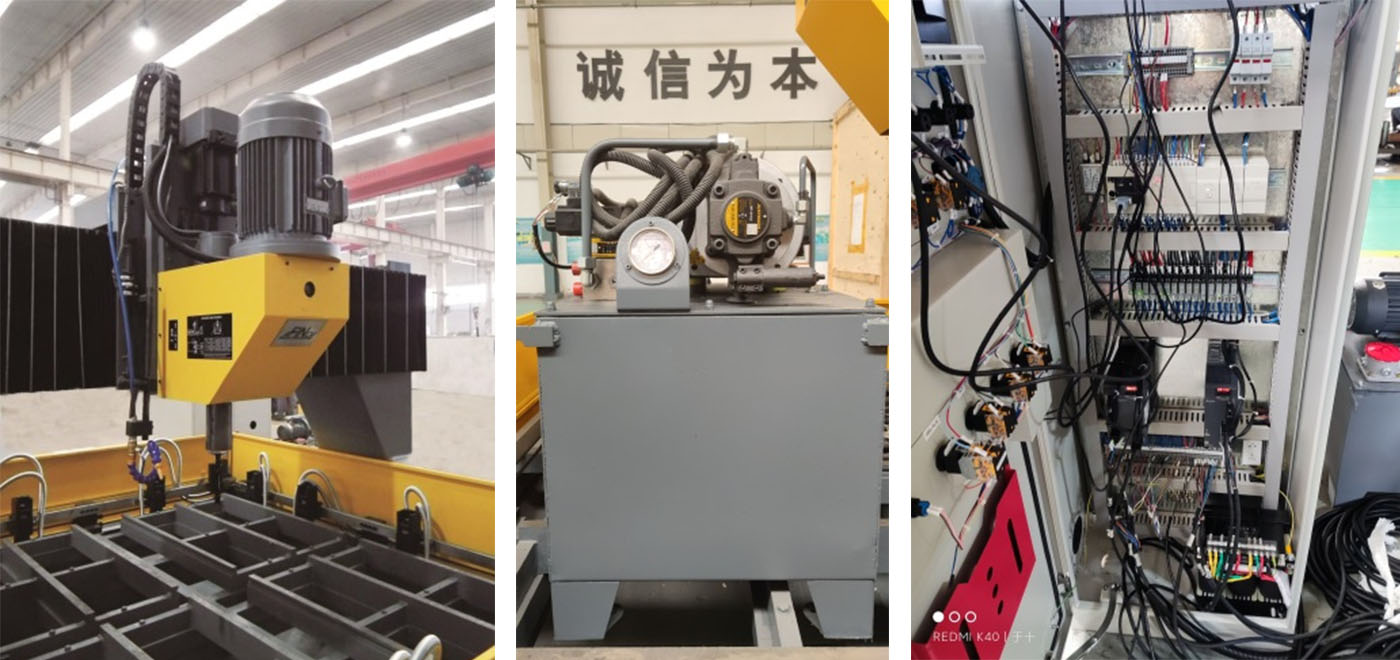

| Edongosolo la magetsi | Dongosolo lowongolera | PLC+ kompyuta yapamwamba |

| Chiwerengero cha nkhwangwa za CNC | 4 |

1. Malo olumikizirana a dzenje akhoza kukhala owonekera mwachangu pa liwiro la 8m/min, ndipo nthawi yothandizira ndi yochepa.

2. Makinawa ali ndi mutu wa mphamvu yobowola wa tebulo lotsetsereka la servo feed. Mota ya spindle ya mutu wa mphamvu yobowola imagwiritsa ntchito malamulo osinthasintha a pafupipafupi osasinthasintha, ndipo liwiro la chakudya limagwiritsa ntchito malamulo othamanga opanda magawo a servo, omwe ndi osavuta kugwiritsa ntchito.

3. Pambuyo pokhazikitsa njira yoyendetsera zinthu zobowolera, imakhala ndi ntchito yowongolera yokha.

4. Bowo lofewa la spindle ndi Morse No.4 ndipo lili ndi chigoba chochepetsera cha Morse no.4/3, chomwe chingagwiritsidwe ntchito kuyika ma drill bits okhala ndi ma diameter osiyanasiyana.

5. Kapangidwe ka gantry mobile kamatengedwa, makinawo amaphimba malo ang'onoang'ono ndipo kapangidwe kake ndi koyenera.

6. Kuyenda kwa X-axis kwa gantry kumayendetsedwa ndi ma linear guide pairs awiri okhala ndi mphamvu yayikulu yonyamula katundu, omwe ndi osinthasintha.

7. Kuyenda kwa mpando wotsetsereka wa Y-axis wa mutu wamagetsi kumayendetsedwa ndi ma peya awiri otsogolera ozungulira, ndipo kumayendetsedwa ndi mota ya AC servo ndi ma screw a mpira olondola, zomwe zimatsimikizira kuti malo obowolera ndi olondola kwambiri.

9. Makinawa ali ndi chipangizo chokhazikitsira zida pakati pa kasupe, chomwe chingathe kudziwa mosavuta malo a flange.

10. Ili ndi chochotsera chip ndi thanki yoziziritsira. Pampu yoziziritsira imazungulira choziziritsira cha kuboola spindle kuti iwonjezere magwiridwe antchito a kuboola ndi moyo wa ntchito ya kuboola.

11. Pulogalamu yowongolera imagwiritsa ntchito PLC ndipo ili ndi kompyuta yapamwamba kuti ithandize kusungira ndi kulowetsa pulogalamu yokonza ma plate, ndipo ntchito yake ndi yosavuta. Pulatifomu ya mapulogalamu ndi ya windows system, yokhala ndi mawonekedwe abwino ogwirira ntchito, kasamalidwe ka zinthu komveka bwino komanso kogwira mtima, komanso ntchito yamphamvu yokonza mapulogalamu; kukula kwa plate kumatha kulowetsedwa ndi kiyibodi pamanja kapena kulowetsedwa ndi mawonekedwe a U-disk.

| Ayi. | Dzina | Mtundu | Dziko |

| 1 | Lnjanji yowongolera yopanda mutu | HIWIN/CSK | Taiwan, China |

| 2 | PLC | Mitsubishi | Japan |

| 3 | Servo motor ndi dalaivala | Mitsubishi | Japan |

| 4 | Kokani unyolo | JFLO | China |

| 5 | Batani, kuwala kosonyeza | Schneider | France |

| 6 | Chokulungira mpira | PMI | Taiwan, China |

Dziwani: Wogulitsa amene ali pamwambawa ndi wokhazikika. Angasinthidwe ndi zinthu zomwezo za mtundu wina ngati wogulitsa amene ali pamwambawa sangathe kupereka zinthuzo ngati pangakhale zinthu zina zapadera.

Mbiri Yachidule ya Kampani  Zambiri Za Fakitale

Zambiri Za Fakitale  Mphamvu Yopanga Pachaka

Mphamvu Yopanga Pachaka  Luso la Malonda

Luso la Malonda