Makina Obowolera a BD200E CNC a Matabwa

| Idzina la tem | Pamita | |||

| BD150C-3 | BD200E-3 | |||

| Muyeso wa maMtengo wa H Beam | Kutalika kwakukulu kwaMzere wa H | 2100mm | 1600mm | |

| Kukula kwakukulu kwaMzere wa H(m'lifupi × kutalika) | 1500*1500mm | 1000*2000mm | ||

| Kukula kochepa kwa gawo laMzere wa H(m'lifupi × kutalika) | 500*500mm | 400 * 1000mm | ||

| Kugwira ntchitotebulo (Fixed) | Kutalika kwa tebulo logwirira ntchito kuchokera pansi | 900mm | ||

| M'lifupi mwa T-slot pa tebulo logwirira ntchito | 28mm | |||

| Kuyenda kwa gantry longitudinal (X-axis) | Kugundana kwa X-axis | 21m | 16m | |

| Mphamvu ya injini ya servo ya X-axis | 2 × 3.0kW | |||

| Kusuntha kwa mbali kwa mutu wamagetsi pa denga la gantry (V-axis) | Kukwapula kwa V-axis | 1500mm | 1980mm | |

| Mphamvu ya injini ya V-axis servo | 1.5KW | |||

| Kusuntha koyima kwa mutu wa mphamvu pa mzere wawiri wa gantry (U-axis, W-axis) | Kugundana kwa U-axis, W-axis | 1500mm | 980mm | |

| Mphamvu ya injini ya servo ya U-axis, W-axis | 2 × 1.5kW | |||

| Kubowola kwa mtundu wa tebulo (mutu wotsetsereka) | Kuchuluka | 3 | ||

| Pazipitadzenjem'mimba mwake pobowola | 12~50 | |||

| ChokulungiraRPM(kutembenuka kwa pafupipafupi 30-100Hz) | 120-400r/mphindi | 120-560r/mphindi | ||

| Mzere wozungulira wa spindle | 4 | 8 | ||

| Mphamvu ya injini ya spindle | 3 × 7.5kW | |||

| Kukwapula kwa Axial (axis imodzi, axis zitatu) | 600mm | 780mm | ||

| Kukwapula kwa Axial (2-axis) | 700mm | 580mm | ||

| Ma drive a 1-axis, 2-axis, 3-axis | Injini ya servo ya AC, screw drive ya mpira | |||

| Chiŵerengero cha chakudya cha 1-axis, 2-axis, 3-axis | 0-4000mm/mphindi | |||

| Mphamvu ya injini ya servo ya 1-axis, 2-axis, 3-axis | 3 × 1.5kW | |||

| Mphamvu ya injini ya pampu ya hydraulic | 3+4kW | |||

| Kuchotsa ndi kuziziritsa tchipisi | Mtundu wa chonyamulira cha chip | Unyolo wosalala | ||

| Liwiro lochotsa chip | 1m/mphindi | |||

| Mphamvu ya injini ya Chip conveyor | 2x0.75KW | |||

| Mphamvu ya injini ya pampu yozizira | 0.45KW | |||

| Edongosolo la magetsi | Dongosolo lolamulira manambala | PLC | ||

| Nambala | 8 | |||

| Mphamvu yonse ya chida cha makina | Pafupifupi 47kw | |||

| Mulingo wonse (L ×W×H) | Pafupifupi 26m × 4.5m × 4.2m | |||

| Kulemera | Pafupifupi matani 60 | |||

1. Makinawa amapangidwa makamaka ndi bedi, gantry, headstock, dongosolo lamagetsi, dongosolo la hydraulic, dongosolo lochotsa chip chozizira, dongosolo lozindikira, ndi zina zotero.

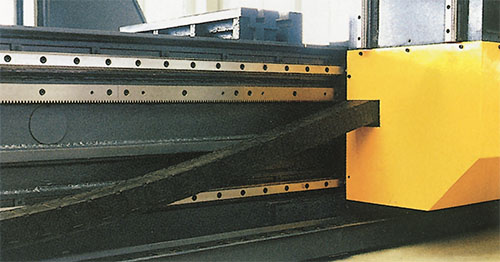

2. Makinawa amatenga kapangidwe ka gantry moving ndi worktable yokhazikika, zomwe zimatha kuchepetsa kutalika kwa bedi ndikusunga malo apansi.

3. Kuyenda kwa gantry (x-axis) kumayendetsedwa ndi mzere wotsogolera mpira, mota ya AC servo ndi rack ndi pinion yotsika. Linear ball guide, mota ya AC servo ndi ball screw drive zimagwiritsidwa ntchito kutsogolera kuyenda kwa gantry crossbeam ndi sliding plate pa mipiringidzo iwiri yoyima (U, V, W). Kuyenda kwa feed kwa mutu uliwonse wobowola (Axis 1, 2 ndi 3) kumayendetsedwa ndi mzere wotsogolera wozungulira, woyendetsedwa ndi mota ya servo ndi screw ya mpira.

4. Spindle imagwiritsa ntchito mutu wa mphamvu ya CNC feed pobowola womwe umapangidwa ndi kampani yathu.

5. Pansi pa makinawo pali chochotsera chip chopangidwa ndi unyolo wathyathyathya, ndipo chonyamulira chip chili ndi pampu yamadzi ndi chipangizo choziziritsira madzi chozungulira.

6. Dongosolo la hydraulic limagwiritsidwa ntchito makamaka poika ma X-axis ndi kutseka ndi kulinganiza mitu yamagetsi mbali zonse ziwiri.

7. Makina amagetsi amayendetsedwa ndi PLC ndipo ali ndi kompyuta yapamwamba. Zinthuzo zimalowetsedwa ndikusungidwa ndi kompyuta, kotero zimakhala zosavuta kugwiritsa ntchito.

| Ayi. | Dzina | Mtundu | Dziko |

| 1 | Peyala yowongolera mpira wolunjika | HIWIN/PMI | Taiwan, China |

| 2 | PLC | Mitsubishi | Japan |

| 3 | Servo motor ndi dalaivala | Mitsubishi / Panasonic | Japan |

| 4 | Valavu yamadzimadzi | ATOS | Italy |

| 5 | Pompo yamafuta | Justmark | Taiwan, China |

| 6 | Batani, kuwala kosonyeza | Schneide | France |

| 7 | Kokani unyolo | JFLP | China |

Dziwani: Wogulitsa amene ali pamwambawa ndi wokhazikika. Angasinthidwe ndi zinthu zomwezo za mtundu wina ngati wogulitsa amene ali pamwambawa sangathe kupereka zinthuzo ngati pangakhale zinthu zina zapadera.

Mbiri Yachidule ya Kampani  Zambiri Za Fakitale

Zambiri Za Fakitale  Mphamvu Yopanga Pachaka

Mphamvu Yopanga Pachaka  Luso la Malonda

Luso la Malonda